Fermenting foods at home has gained popularity for its health benefits and unique flavors. Creating an organized kitchen fermentation station streamlines the process, making it easier and more enjoyable. A well-designed fermentation area includes dedicated workspace, proper equipment, and efficient storage solutions.

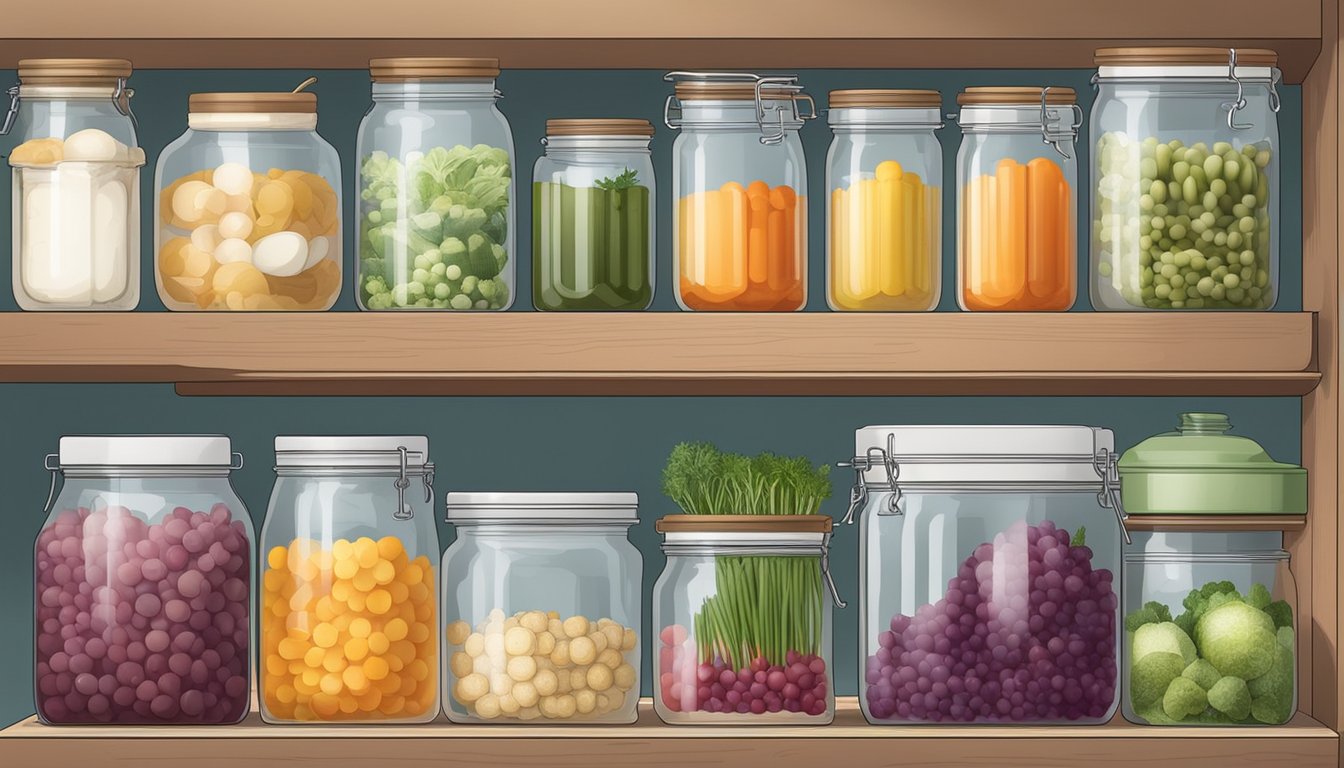

An effective fermentation station starts with selecting the right location in your kitchen. A countertop or kitchen island provides ample space for preparation and monitoring. Essential equipment includes glass jars, airlocks, weights, and fermentation-specific tools. Organizing these items in easily accessible containers or shelves keeps the workspace tidy and functional.

Proper organization of a fermentation station also involves considering temperature control and lighting. Some ferments require specific temperature ranges, so incorporating a thermometer or heating pad may be necessary. By thoughtfully arranging your fermentation area, you create an inviting space that encourages regular use and experimentation with various fermented foods.

Understanding the Fermentation Process

Fermentation transforms foods through microbial action, creating flavorful and nutritious products. This ancient preservation technique harnesses natural processes to develop unique tastes and textures.

The Science Behind Fermentation

Fermentation occurs when microorganisms break down carbohydrates in an anaerobic environment. Bacteria, yeasts, or molds convert sugars into acids, gases, or alcohol. This process alters the food’s chemistry, extending shelf life and enhancing flavor.

Lactic acid bacteria are common in vegetable fermentation. They produce lactic acid, lowering pH and inhibiting harmful bacteria growth. Yeasts generate carbon dioxide and ethanol, crucial in bread-making and brewing.

Different microbes yield diverse outcomes. For example:

- Lactobacillus in yogurt and pickles

- Saccharomyces in beer and wine

- Acetobacter in vinegar production

Temperature, salt concentration, and time influence fermentation results. Controlling these factors ensures consistent, safe products.

Benefits of Home Fermentation

Home fermentation offers numerous advantages. It creates probiotic-rich foods that support gut health and boost the immune system. These beneficial microorganisms aid digestion and nutrient absorption.

Fermented foods develop complex flavors. The process enhances umami taste, adding depth to dishes. Popular examples include:

- Tangy sauerkraut

- Savory miso

- Effervescent kombucha

Fermenting at home allows control over ingredients and processing. This ensures higher quality and potentially healthier outcomes than some commercial alternatives.

Home fermentation is cost-effective. It transforms inexpensive ingredients into valuable, nutritious foods. The process also reduces food waste by preserving surplus produce.

Engaging in fermentation connects practitioners to culinary traditions. It fosters creativity in the kitchen and promotes a deeper understanding of food science.

Choosing the Right Equipment

Selecting appropriate equipment is crucial for creating an effective fermentation station. The right tools ensure successful ferments and streamline your process.

Selecting Proper Fermentation Vessels

Glass jars are ideal for fermentation due to their non-reactive nature. Mason jars and canning jars work well for small batches. For larger quantities, consider dedicated fermentation crocks.

Wide-mouth jars make it easier to pack vegetables and remove finished ferments. Look for vessels with airtight lids to prevent oxygen from entering.

Some fermentation jars come with built-in airlocks, simplifying the setup. Choose sizes appropriate for your typical batch sizes to avoid wasting space.

Using Airlocks and One-Way Valves

Airlocks and one-way valves allow carbon dioxide to escape while preventing oxygen from entering. This creates an anaerobic environment essential for successful fermentation.

Airlock systems can be as simple as a rubber stopper with a water-filled S-shaped tube. More modern options include silicone one-way valves that fit directly onto mason jar lids.

These devices help prevent mold growth and maintain the integrity of your ferments. They’re especially useful for longer fermentation periods.

The Importance of Fermentation Weights

Weights keep vegetables submerged below the brine, preventing exposure to air and potential spoilage. Glass weights designed specifically for fermentation jars are popular.

Ceramic weights offer another non-reactive option. Some fermenters use water-filled plastic bags as makeshift weights.

For narrow-mouth jars, consider using a cabbage leaf or other large vegetable piece as a follower to hold ingredients down.

Proper weighting ensures even fermentation and reduces the risk of surface mold.

Temperature Control Tools

Maintaining consistent temperature is key for optimal fermentation. A simple thermometer helps monitor ambient temperature in your fermentation area.

For more precise control, consider a temperature controller paired with a heating pad. This setup allows you to maintain specific temperatures for different ferments.

In warmer climates, you might need a dedicated cooler area to prevent over-fermentation. A small refrigerator with a temperature controller can serve this purpose.

Tracking temperature over time helps you understand how it affects your ferments’ flavor and texture.

Setting Up The Fermentation Station Layout

A well-designed fermentation station layout optimizes space, enhances efficiency, and ensures ideal conditions for your ferments. Proper placement and organization of equipment create a functional workspace that facilitates consistent results.

Finding the Perfect Spot

Choose a location away from direct sunlight and heat sources. A cool, dark corner of the kitchen or pantry works well. Ensure adequate ventilation to prevent mold growth.

Consider proximity to power outlets for temperature controllers and other equipment. Measure the available space to determine how many fermentation vessels can fit comfortably.

Stable surfaces are crucial. Install sturdy shelving or use a dedicated table to support the weight of multiple fermentation jars.

Arrangement for Maximum Efficiency

Group similar items together. Place frequently used tools within easy reach. Store less common equipment in nearby drawers or cabinets.

Use tiered shelving to maximize vertical space. Place larger fermentation vessels on lower shelves for stability. Smaller jars and bottles can go on upper levels.

Implement a labeling system for jars and ingredients. Clear labels help track fermentation progress and expiration dates.

Consider a mobile cart for flexibility. This allows you to move your fermentation station as needed.

Maintaining an Oxygen-Free Environment

Create separate zones for aerobic and anaerobic ferments. Use airlock systems for oxygen-sensitive ferments like sauerkraut or kimchi.

Invest in quality fermentation lids with built-in airlocks. These allow gases to escape while preventing oxygen from entering.

Store extra jar lids, airlocks, and weights nearby. Having these on hand ensures you can quickly seal new ferments.

Use food-grade silicone or glass weights to keep vegetables submerged in brine. This prevents mold growth on the surface.

Monitoring and Adjusting the Environment

Install a wall-mounted thermometer to track ambient temperature. For precise control, use a temperature controller with a heating pad or cooling element.

Keep pH strips or a digital pH meter accessible. Regular pH testing helps monitor fermentation progress and detect issues early.

Use hygrometers to measure humidity levels. High humidity can lead to mold growth, so consider using a dehumidifier if needed.

Place an activated carbon filter nearby to absorb odors. This helps prevent cross-contamination of flavors between different ferments.

Store a log book or digital device for recording fermentation data. Tracking temperature, pH, and observations helps refine your process over time.

Ingredients and Preparations

Selecting quality ingredients and proper preparation are crucial for successful fermentation. These steps lay the foundation for creating delicious and nutritious fermented foods.

Choosing High-Quality Ingredients

Fresh, organic produce is ideal for fermentation. Choose vegetables at their peak ripeness for the best flavor and nutritional value. Cabbage is a popular choice for making sauerkraut and kimchi. Look for firm heads without blemishes or wilted leaves.

For salt, use non-iodized varieties like sea salt or kosher salt. Iodized salt can interfere with the fermentation process.

When making sourdough, use high-quality flour and filtered water. The type of flour affects the flavor and texture of the final product.

Preparing Ingredients for Fermentation

Clean all produce thoroughly to remove dirt and potential contaminants. Chop or shred vegetables uniformly to ensure even fermentation.

For cabbage-based ferments, massage salt into the shredded leaves to release their natural juices. This creates the brine necessary for fermentation.

Prepare a saltwater brine for other vegetables using the correct salt-to-water ratio. This solution provides an ideal environment for beneficial bacteria to thrive.

Measure ingredients accurately, especially when following specific recipes. Proper ratios are essential for successful fermentation and food safety.

Fermenting Different Foods and Beverages

Fermentation transforms ordinary ingredients into flavorful, probiotic-rich foods and drinks. This process unlocks unique tastes and health benefits across a variety of culinary creations.

Vegetables and Pickles

Fermenting vegetables is a simple way to preserve produce and create tangy, crunchy pickles. Start with clean, fresh vegetables and submerge them in a salt brine solution. Popular choices include cucumbers, cabbage for sauerkraut, and mixed vegetables for kimchi.

Use glass jars with airlocks to prevent unwanted bacteria. Keep vegetables submerged using weights or cabbage leaves. Ferment at room temperature for 3-10 days, depending on desired flavor intensity.

Check progress daily, removing any surface mold. Once ready, transfer to the refrigerator to slow fermentation. Enjoy your homemade pickles within a few months for optimal taste and texture.

Culturing Dairy and Non-Dairy Kefir

Kefir is a fermented milk drink rich in probiotics. To make dairy kefir, add kefir grains to milk and let sit at room temperature for 24 hours. Strain out the grains and enjoy the tart, creamy beverage.

For non-dairy options, use water kefir grains with sugar water or coconut water. These produce a lighter, effervescent drink. The Kefirko fermenting system simplifies the process for both types.

Experiment with second fermentations by adding fruit or herbs for extra flavor. Store finished kefir in glass bottles in the refrigerator for up to two weeks.

Brewing Kombucha and Other Fermented Drinks

Kombucha is a fermented tea beverage made using a SCOBY (symbiotic culture of bacteria and yeast). Brew sweetened tea, add the SCOBY, and ferment for 7-10 days. The result is a tangy, slightly fizzy drink.

For a fruitier flavor, add juice during a second fermentation. Other fermented drinks include kvass (made from rye bread) and jun (green tea and honey kombucha).

Use flip-top bottles for carbonation and store in a cool, dark place. Always use caution when opening fermented beverages, as pressure can build up during the process.

Maintenance and Troubleshooting

Proper maintenance and troubleshooting are crucial for successful fermentation. Regular cleaning, sterile equipment, and addressing common issues ensure high-quality fermented foods and beverages.

Cleaning and Sterilizing Equipment

Clean all fermentation vessels and utensils thoroughly after each use. Wash with hot, soapy water and rinse well. For deeper cleaning, use a solution of 1 tablespoon white vinegar per cup of water.

Sterilize equipment by boiling for 10 minutes or using a sanitizing solution. Pay special attention to air-valves and auto-burping mechanisms on fermentation vessels.

Allow all items to air dry completely before storage. This prevents moisture buildup that can lead to mold growth.

Inspect mason jars and other containers regularly for chips or cracks. Replace damaged items to maintain a sterile environment.

Solving Common Fermentation Issues

Monitor ferments daily for signs of contamination. Discard any batches with fuzzy mold growth or foul odors.

If fermentation seems slow, check the ambient temperature. Most ferments thrive between 65-75°F (18-24°C).

For mushy vegetables, increase salt content slightly in future batches. Aim for a 2-3% salt brine by weight.

Address kahm yeast (white film on surface) by skimming it off. This harmless yeast won’t affect the final product.

To combat fruit flies, use tighter-fitting lids or cover fermentation vessels with a fine mesh cloth.

For overly sour ferments, reduce fermentation time or lower the temperature in future batches.