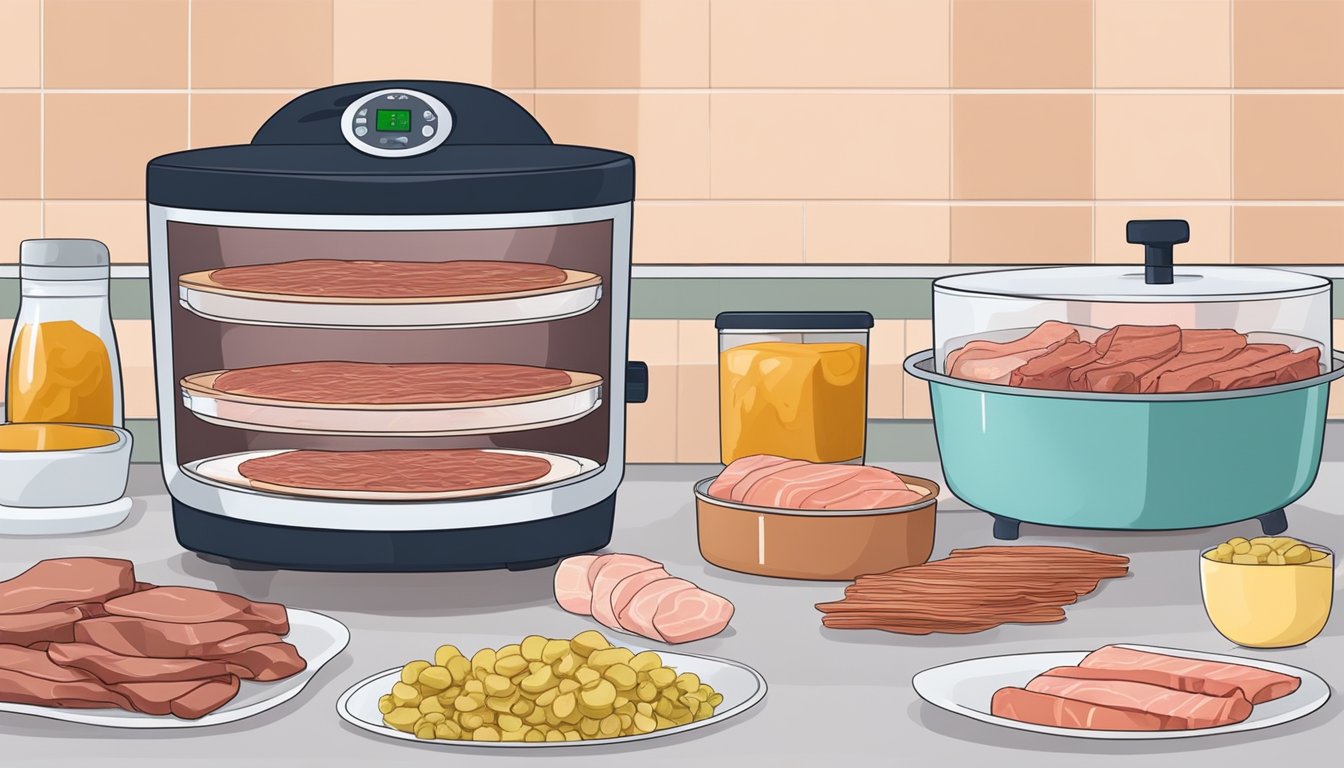

Making your own beef jerky at home with a dehydrator is a rewarding process that yields delicious results. This protein-packed snack not only satisfies cravings but also offers a healthier alternative to store-bought versions. With a dehydrator, some quality beef, and the right marinade, you can create flavorful jerky tailored to your taste preferences.

The key steps involve selecting lean cuts of beef, trimming excess fat, slicing the meat uniformly, and marinating it for several hours. Once prepared, the beef strips are arranged on dehydrator trays and dried at a low temperature for several hours. This method ensures safe preservation while concentrating the meat’s flavors.

Homemade jerky allows for experimentation with various marinades and seasonings. From classic teriyaki to spicy sriracha, the flavor possibilities are endless. By controlling the ingredients, you can also reduce sodium and eliminate preservatives commonly found in commercial jerky products.

Understanding the Jerky-Making Process

Making jerky at home with a dehydrator allows for customization and quality control. This process involves selecting the right meat, understanding the benefits of homemade jerky, and utilizing the proper dehydrator features.

Choosing the Right Cut of Meat

The best cuts for homemade beef jerky come from lean parts of the cow. Eye of round, bottom round, top round, and london broil are excellent choices. These cuts have minimal fat, which is crucial for creating jerky that lasts longer.

Lean meat prevents rancidity and spoilage during storage. A round roast can also be used, but trim any visible fat before slicing. When selecting meat, look for deep red color and avoid pieces with excessive marbling.

Cut the meat against the grain for tender jerky, or with the grain for a chewier texture. Aim for slices about 1/4 inch thick for optimal drying.

Benefits of Homemade Jerky Over Store-Bought

Homemade beef jerky offers several advantages over its store-bought counterpart. Control over ingredients is a key benefit, allowing for customization of flavors and reduction of preservatives.

Homemade jerky typically contains less sodium and sugar than commercial versions. It’s free from artificial additives and colorings often found in store-bought products.

The cost-effectiveness of making jerky at home can be significant, especially when buying meat in bulk. Freshness is another advantage, as homemade jerky can be consumed immediately after drying.

Quality control ensures that only the best cuts of meat are used, unlike some mass-produced jerky that may use lower-grade meat.

Essential Dehydrator Features

A reliable dehydrator is crucial for making high-quality beef jerky at home. Look for models with adjustable temperature controls, typically ranging from 95°F to 165°F.

Consistent airflow is essential for even drying. Choose a dehydrator with a fan that circulates air efficiently throughout the unit. Multiple trays allow for larger batches and better air circulation.

A timer function is helpful for precise drying times. Some advanced models include pre-programmed settings for jerky. Removable, dishwasher-safe trays make cleaning easier after use.

Consider the noise level, especially if planning to run the dehydrator overnight. Energy efficiency is also important for long drying sessions.

Preparing the Meat

Proper meat preparation is crucial for creating high-quality jerky. This process involves carefully trimming excess fat, slicing the meat to the right thickness, and employing tenderizing techniques to enhance texture and flavor absorption.

Trimming and Slicing

Start by selecting lean meat cuts like top round or eye of round. Trim off all visible fat, as it can turn rancid during drying. Place the meat in the freezer for 1-2 hours until firm but not frozen solid. This makes it easier to slice uniformly.

Using a sharp knife, cut against the grain into 1/4-inch thick slices. Consistent thickness ensures even drying. For a chewier texture, slice with the grain instead.

Consider investing in a meat slicer for perfectly uniform cuts. This tool is especially useful when making large batches of jerky.

Meat Tenderizing Techniques

Tenderizing helps create a more palatable jerky texture and allows marinades to penetrate deeper. One method is mechanical tenderizing using a meat mallet or tenderizer tool with small blades.

Another effective technique is enzymatic tenderizing. Use natural enzymes found in pineapple, papaya, or kiwi juice. Mix a small amount into your marinade, but be cautious as over-tenderizing can make the meat mushy.

For tougher cuts, consider using a commercial meat tenderizer powder. Apply it sparingly before marinating to avoid overpowering the meat’s natural flavor.

Properly tenderized meat absorbs marinades more readily, resulting in more flavorful jerky. Experiment with different methods to find your preferred texture and taste.

Crafting Your Jerky Marinade

A flavorful marinade is essential for creating delicious homemade jerky. The right blend of ingredients will infuse the meat with taste and help preserve it during the dehydration process.

Classic Marinade Ingredients

A traditional jerky marinade combines savory and sweet elements. Soy sauce forms the base, providing saltiness and umami. Worcestershire sauce adds depth and tang. Brown sugar balances the flavors with a touch of sweetness. Garlic powder and onion powder contribute aromatic notes. Black pepper and salt enhance the overall taste profile.

Liquid smoke imparts a subtle smoky flavor, mimicking the taste of traditional smoking methods. For added complexity, include a dash of smoked paprika. Blend these ingredients thoroughly in a bowl or zip-top bag before adding the meat slices.

Creating a Spicy Marinade Variation

For those who enjoy a kick, a spicy marinade offers an exciting alternative. Start with the classic base of soy sauce and Worcestershire sauce. Add red pepper flakes for heat and texture. Cayenne pepper intensifies the spiciness while contributing a distinct flavor.

Incorporate honey instead of brown sugar to balance the heat with natural sweetness. Garlic powder and onion powder remain essential for depth. A pinch of black pepper complements the other spices. For an extra layer of heat, add a small amount of hot sauce or chipotle powder.

Mix all ingredients well before marinating the meat. Adjust the spice levels to suit personal preferences. Remember that flavors intensify during the dehydration process.

Drying the Jerky

The drying process is crucial for creating safe, flavorful beef jerky. Proper dehydrator setup and timing ensure the best results.

Setting Up the Dehydrator

Place jerky strips on dehydrator racks with space between each piece for air circulation. This allows even drying throughout the batch.

Set the initial temperature to 165°F (74°C) for the first 3 hours. This step is essential for food safety, bringing the internal meat temperature to 160°F (71°C).

After 3 hours, reduce the dehydrator temperature to 145°F (63°C) for the remainder of the drying time.

Arrange thicker strips on upper racks and thinner pieces on lower racks. This compensates for any temperature variations within the dehydrator.

Determining Optimal Drying Time

Total drying time typically ranges from 4 to 6 hours, depending on meat thickness and desired texture.

Begin checking jerky at the 4-hour mark. Properly dried jerky should bend and crack but not break in half when folded.

Remove pieces as they finish drying to prevent over-drying. Thinner slices may be ready earlier than thicker ones.

Continue checking every 30 minutes until all pieces reach the right consistency. Well-dried jerky has a dark color and slightly leathery texture.

Oven Drying Option

Making jerky in an oven is a viable alternative to using a dehydrator. This method allows you to create homemade jerky using equipment you likely already have in your kitchen.

Oven Preparation

Preheat the oven to its lowest setting, ideally between 165°F and 175°F. Line baking sheets with aluminum foil for easy cleanup. Place wire racks on the baking sheets to allow air circulation around the meat.

Arrange marinated meat strips on the racks, ensuring they don’t touch. Leave space between pieces to promote even drying. Prop the oven door open slightly with a wooden spoon to allow moisture to escape.

Monitor the jerky closely during the drying process. Oven drying typically takes 4-8 hours, depending on meat thickness and desired texture. Check the jerky every hour, rotating trays for even drying.

Test for doneness by bending a piece. It should crack but not break. Remove jerky when it reaches the desired consistency. Let cool before storing in airtight containers.

Storing Your Homemade Jerky

Proper storage is crucial for maintaining the quality and safety of homemade jerky. Choosing the right container and knowing how long jerky can be kept are key factors in preserving its flavor and texture.

Choosing the Right Storage Solution

Airtight containers are essential for storing homemade beef jerky. Mason jars with tight-fitting lids work well for short-term storage. For longer preservation, vacuum-sealed bags are an excellent choice. These bags remove air, preventing moisture and bacteria growth.

Plastic zipper bags can be used if jerky will be consumed within a week. It’s important to squeeze out as much air as possible before sealing. For added protection, placing a food-grade desiccant packet in the container can help absorb any remaining moisture.

Avoid storing jerky in paper bags for extended periods, as they don’t provide adequate protection against air and moisture.

How Long to Keep Jerky

Homemade beef jerky typically lasts 1-2 months when stored in an airtight container at room temperature. Refrigeration can extend its shelf life to 3-6 months. For even longer storage, jerky can be frozen for up to a year.

It’s crucial to check jerky regularly for signs of spoilage. Any visible mold, off-odors, or changes in texture indicate that the jerky should be discarded. Properly dried jerky should be tough and leathery, not soft or moist.

Vacuum-sealed jerky can last up to 6 months at room temperature and up to a year in the refrigerator. Always label containers with the date of preparation to track storage time.

Advanced Jerky Making

Advanced jerky making techniques allow for greater customization and texture control. Specialized tools and methods can elevate your homemade jerky to new levels of taste and consistency.

Using a Jerky Gun for Ground Beef Jerky

A jerky gun is a valuable tool for creating uniform strips of ground beef jerky. Load seasoned ground beef into the gun’s chamber and extrude it onto dehydrator trays in consistent shapes. This method produces tender jerky with a softer texture than whole muscle cuts.

Ground beef jerky offers more versatility in flavoring. Mix spices directly into the meat for even distribution. Experiment with different fat percentages to find your ideal balance of flavor and texture.

To use a jerky gun:

- Mix seasonings into ground beef

- Load the mixture into the gun

- Squeeze out strips onto dehydrator trays

- Dehydrate at 165°F for 4-6 hours

For chewier ground beef jerky, add a binder like eggs or breadcrumbs. This helps the meat hold together during drying. Adjust drying time based on desired texture, checking regularly to prevent over-drying.

Creating Your Own Beef Jerky Recipe

Crafting a personalized beef jerky recipe allows for customization of flavors and textures. Start with selecting high-quality, lean meat such as eye of round roast. Trim off any visible fat to prevent spoilage during the drying process.

For the marinade, combine soy sauce, Worcestershire sauce, and honey as a base. Add garlic powder, onion powder, and black pepper for depth. Experiment with additional spices like chili flakes or liquid smoke to create unique flavor profiles.

Slice the meat thinly, no thicker than 1/4 inch, against the grain for tender jerky. Marinate the strips for 3-24 hours in the refrigerator, ensuring even coating.

Arrange the marinated strips on dehydrator trays, leaving space between each piece for air circulation. Set the dehydrator to 165°F (74°C) for the first 3 hours, then reduce to 145°F (63°C) for the remaining time.

Drying times vary, but typically range from 4-8 hours. The jerky is ready when it bends and cracks but doesn’t break. Store in airtight containers for optimal freshness.

Remember to follow food safety guidelines throughout the process to ensure a safe, delicious homemade beef jerky.